Electrostatic Precipitator Prinicipal

An electrostatic precipitator is air pollution control device used to separate solid particulate matter from a contaminated air stream. Contaminated air flows into an ESP chamber and is ionized by electron emitting electrodes; also known as the corona chamber. The suspended particles are charged by the electron field and migrate to a collection plate. Accumulate particulate matter is removed from the collection plates at periodic intervals by rapping or hitting the plates with rappers (mallets type hammers). Heavy particles fall to the base of the ESP where hoppers hold the removed particles for disposal.

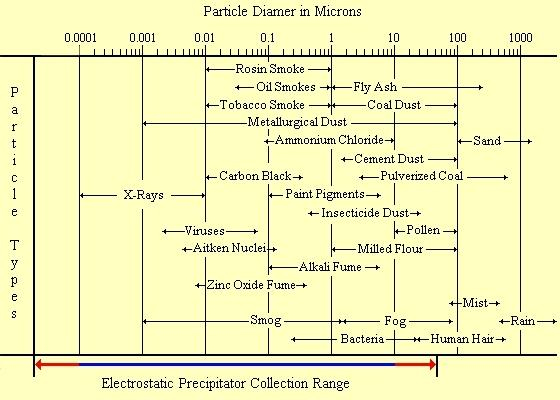

Electrostatic precipitators are used to separate small particles, 1 micron or smaller, from gas streams. This process is also used in desalters to separate salts and sediment from crude oil feeds.

GENERAL INFORMATION

Electrostatic precipitators, such as the one shown here, work by exposing particles in the feed stream to an electrostatic field. The particles are small and easily collect a charge. The charged particles are then collected and removed by collectors that are oppositely charged.

The collectors get covered with particles and are cleaned off periodically. The particles are generally discarded but can be further processed if profitable.

Electrostatic precipitators can collect a variety of particles from a gas stream. The table below shows the wide range of collection sizes in gas streams, from as small as x-rays and smog to as large as fly ash and pulverized coal.

Wet Electrostatic Precipitators

In wet electrostatic precipitators, charged particles (green) are collected onto the collectors as seen in the animation here. As the particles accumulate on the collector, a liquid (blue), typically water, runs down the plates. The water collects and removes the particles from the plates.

USAGE EXAMPLES

Electrostatic precipitators are used in a variety of industries for emission reduction of particles to control air pollution. The picture shown below is of a refinery boiler that has a wet electrostatic precipitator installed for treatment of flue gas emissions.

The following is a small list of typical industrial applications for ESPs.

Refuse & sewerage sludge dryers and incinerators

Coal- and oil-fired boilers, coal driers and coal mills

Production plants for the cement, limestone, gypsum, pulp and paper industry (kilns, mills, driers and coolers)

Electro-metallurgical, chemical, gas and detergent manufacturing plants

SO2, SO3, acid mist and ammonia control (wet ESPs)